Have you ever needed to securely hold an item while working on it? How about connecting two things with force for a temporary or permanent application? This is done with a clamp, and people implement these devices in their everyday work.

Clamps are versatile machines used in carpentry, welding, construction and woodworking, as well as in commercial, industrial, and even medical applications, and they are vital for fastening and holding things. Still, wondering what clamps can be used for?

Here are the eight different types of clamps and their uses:

Type #1: Hand Clamps

These types of clamps often come to mind and are used to temporarily hold or position material being worked on. They are easily secured using your hands and quick release for a different adjustment or placement on the surface you are tightening to.

Hand clamps come in several styles, including:

- Bar clamp

- C clamp

- Locking clamp

- Screw clamp

- Trigger clamp

- Hinge clamp

- Bench clamp

- Band clamp

- Sash clamp

- Action clamp

- Strap clamp

These and other clamps make constructing and fabricating much easier, giving you extra hands to hold things while working on them.

Type #2: Pipe Clamps

A pipe clamp is for securing and hanging pipes in different applications like plumbing, conduit, and exhaust pipes, where you need to mount a pipe at elevation and secure it in place. These types of clamps are mostly used in construction and are often hidden in ceilings and pipe chases. You can see them in parking structures, carrying sprinklers and sewage pipes on the ceilings.

Type #3: Modular Connectors

A modular clamp is designed to connect pipes and tubes quickly for various structural and construction applications. These clamp fittings provide a connection point for two tubes to come together. They create a secure joint using a socket screw for a stronghold. For example, a corner clamp is specifically designed to slot into corners of buildings. Likewise, shelving clamps are appropriate for shelves and cabinets.

The most popular types of fastening clamps include:

- Tee clamps

- Corner clamps

- Angle clamps

- Elbow clamps

- Cross pipe clamps

- Coupling clamps

Other modular connectors include:

- Railing clamps

- Swivel clamps

- Shelving clamps

- Hinge clamps

- Mounting clamps

They are easy to assemble and disassemble and are used for various projects in different industries.

Type #4: Wire Rope Clamps

This clamp is designed to secure wire rope, becoming a rigid line. It is a rigging piece of hardware and can secure a wire along a path for a tie-off point or guard rail, form an end termination, or connect two cables. These cables support and move loads, so there must be a solid connection for safety. They are made of metal with bolts that tighten down to make the cable immovable.

Type #5: Hose Clamps

A hose clamp is a circular-shaped metal clamp that tightens and loosens using a fixed bolt that turns and advances the strap. It can be used for holding together two pipes or other cylindrical objects, such as in construction and the automotive field. They are generally a permanent connection, although they easily loosen and tighten for repairs and replacements of piping.

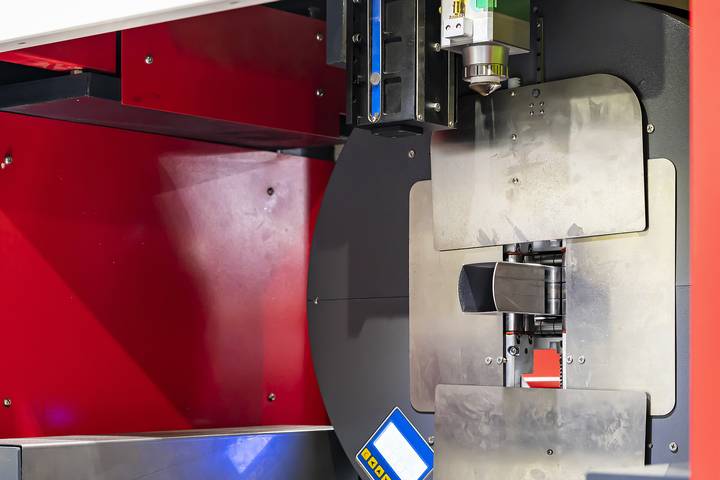

Type #6: Material Handling Clamps

These clamps are used to lift, move and manipulate heavy material in construction, automotive, mechanical, industrial and fabricating operations. They typically are hung overhead, connected to large chains and gears, but they are the grab point for material. Material handling clamps have a large load capacity with jaws at the open end that friction grips the material with the weight tightening the clamp.

Type #7: Medical & Surgical Clamps

Medical and surgical clamps are tools designed to hold and handle objects without using hands and have actionable movements for different medical procedures. These tools help to manipulate organs and tissues during operations and are also used for:

- Dissecting

- Squeezing

- Capturing

- Separating

They come in many different shapes and configurations for different purposes and are vital to health care.

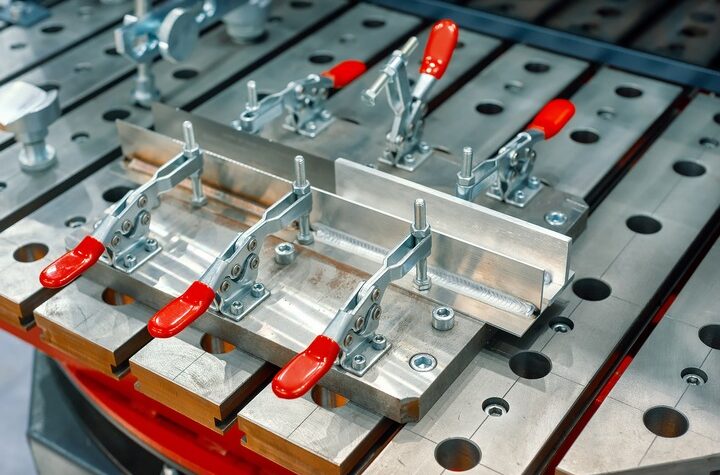

Type #8: Pneumatic Power Clamps

These mechanical devices apply a clamping load with compressed air and hold material in place while working on it, typically in welding on an assembly application. They replaced manual clamping in the automotive industry but are used anywhere a robust clamp is required in an automated setting.

Power clamps have an arm that rotates and pivots into its closed position with a toggle mechanism and is a reliable device, so you have free use of your hands.

Other clamps include:

- Pinch dog

- MITRE

- Drill press

- Pennington

- Corner

- Ear

- Flooring

- Picture frame

A clamp is designed for anything that needs a secure, tight, temporary, or permeant connection. Clamps are versatile and allow easy work on big and small projects without needing to hold your material simultaneously. Understanding the types of clamps will allow you to pick the right tool for the application you are working on.