3D printing is no longer a novelty. Just a few years ago, this innovative printing technique was limited only to large academic institutions, but this is no longer the case. As technology advances, 3D printers have become more advanced, compact, and affordable for the masses.

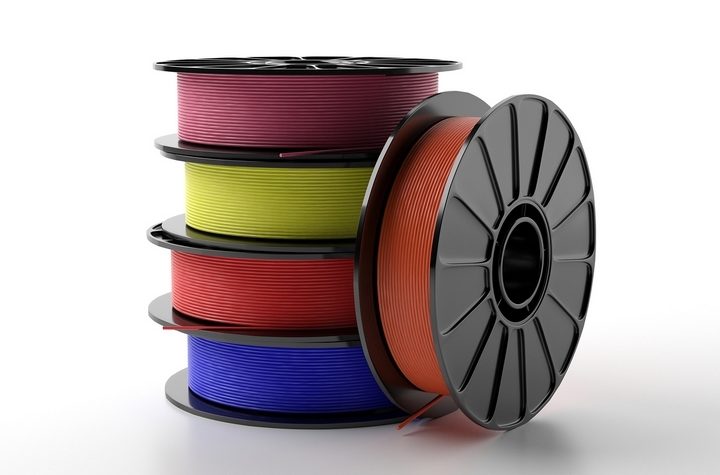

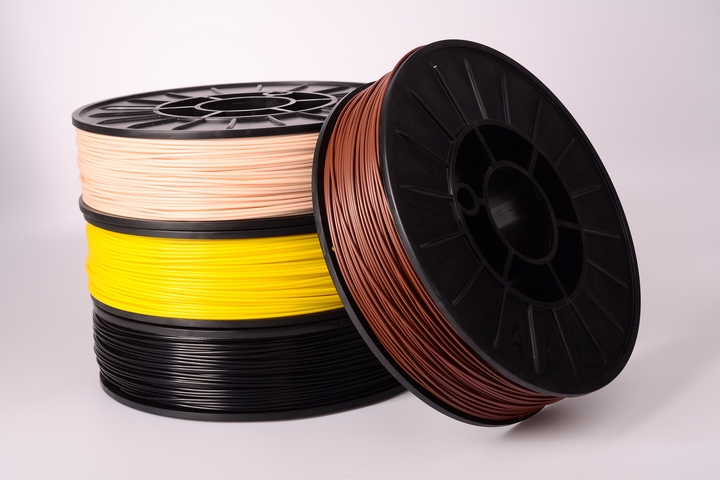

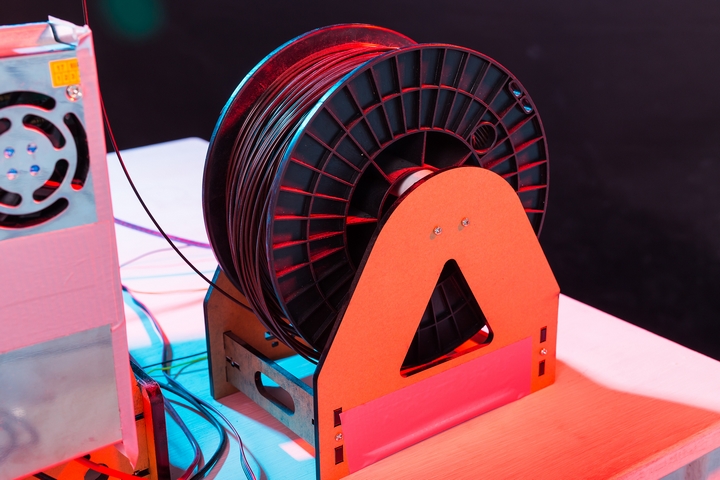

Today, 3D printing is often used in the home, schools, and different types of industries, particularly healthcare. Most of these machines come with a simple roll of filament that is ready for use. But the question is: If the roll does not last long enough, what other 3D printing material can you use?

Before you rush off to buy the latest 3D printer, it is important to know the different types of 3D printing material available, their compatibility with your printer, the costs, and other pros and cons.

Here are eight different 3D printing materials that are commonly used across industries:

1. Acrylonitrile Butadiene Styrene (ABS)

This is a durable plastic material also used to make Legos and many other toys. It is non-toxic, chemical, water-resistant, and long-lasting. The key reason for its wide usage is that it can be easily shaped and molded. It also requires intense heat before it can be damaged. These features make it great for 3D printing.

However, when heated to very high temperatures, these types of 3D printing materials can generate a smell; hence ventilation is required. It costs about $30 per kilo.

2. Polylactic Acid (PLA)

PLA is a plastic polymer made from materials like sugarcane residue. It has features similar to biodegradable plastic packing. PLA is resilient, durable, and opaque. The downside is that it can deform even at low temperatures and is not chemical or water-resistant. It is usually preferred for low-cost 3D printers that are used to make general printing materials.

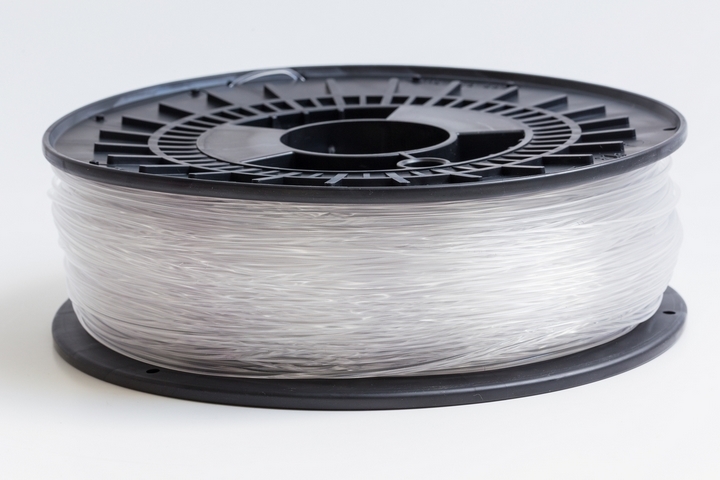

3. Polyvinyl Alcohol

Polyvinyl alcohol is a novel 3D synthetic polymer printing material that is water-soluble. It is often used to make supports and joints that hold the 3D printing together. While the material does not require excessive heat to become pliable, it does release noxious chemicals at high temperatures. This material requires proper disposal methods and costs around $100 per kg.

4. Nylon

Nylon was developed as a replacement for silk and is a rough material with good tensile strength. It requires high temperatures to melt and is non-toxic. Today, it is fast becoming the material of choice for 3D printing as it is resistant to damage and is usually not affected by other chemicals. Nylon is also cheap at $18/kg.

5. High-Density Polyethylene

High-density polyethylene is widely used in 3D printing to make plastic bottles and containers. It is a light material with great flexibility. It is easy to mold and dye, is resistant to most chemicals, and melts at around 230 degrees. However, it can release noxious fumes at high temperatures. The different types of 3D printing materials can be dissolved by immersing the print in limonene. It costs about $30/kg.

6. Polyethylene Terephthalate (PETT)

Polyethylene terephthalate (PETT), also known as t-glase, is often used to make garments. It melts at 230 degrees and can be dyed. It is also used to make utensils like cups, dishes, bowels, etc. The downside to this material is that the printing has to be done slowly to ensure that the layers adhere properly. It costs about $30/kg.

7. Wood Filament

Wood Filament is not made of wood but fine wood particles that are combined with PLA. The finished product looks like wood. The material is printed is the same as PLA filaments, and it costs $100/kg. There are many different types of wood filaments that you can choose from, including birch, coconut, bamboo, timber, cedar, and many others. Wood filaments usually contain 70% PLA and 30% wooden fiber.

8. Metal Filament

The metal filament is another option. It is made of finely ground metals and combined with polymer glue and PLA. Metal filaments are made with a fine metal powder such as bronze, brass, copper, or stainless steel. However, the quantity of metal powder that is infused in the filament varies depending on the manufacturer of the metal filament. The finished product when you use metal filament feels and looks like metal. Polishing may be required if you want to enhance its look and overall appearance.

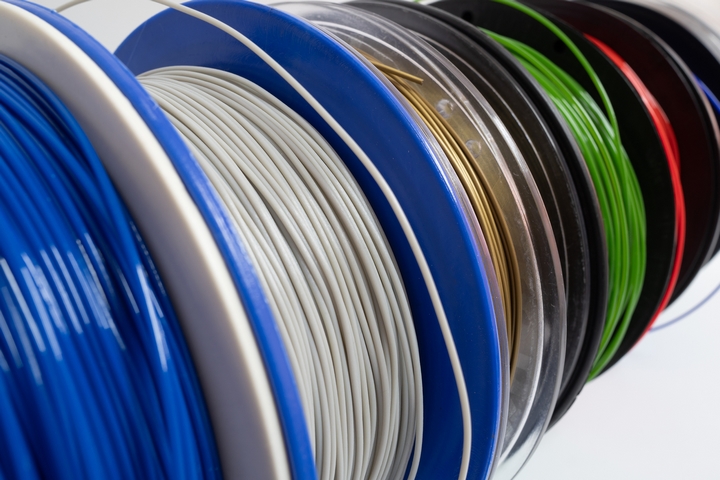

There are different types of 3D printing materials that can also be used. These include carbon fiber mix, flexible filament, and conductive filament.

The decision with respect to which material to use is usually dependent on the output that you expect from your 3D printer. But there are many options, and you need to decide based on your budget, your objective and the quality you require.

Also, since most people are still new to using 3D printing, it is always important to buy a small quantity of the printing material and experiment with it until you get the desired result. Evaluate your options, see the samples for each type of printing material, and then decide which material would suit you best.